Against the sweeping tide of manufacturing’s shift toward high-endization and intelligence, dual-spindle CNC lathes have undergone a remarkable evolution—transcending their traditional role as mere machining tools to emerge as the backbone of precision manufacturing. What sets them apart is their ability to deliver efficient, integrated processing, a feature that has become indispensable in today’s fast-paced, quality-driven industrial landscape. At the forefront of this transformation stands Shandong Hengxing Heavy Industry Technology Co., Ltd., a company deeply committed to advancing this technology. Through relentless technological iteration and innovative functional upgrades, Hengxing Heavy Industry has developed dual-spindle CNC lathes that not only meet the stringent high-precision part processing demands of industries like automotive and aerospace but also serve as a catalyst for breaking through long-standing barriers in flexible production and intelligent collaboration. These lathes are not just pieces of equipment; they are enablers of change, helping manufacturers streamline operations, reduce costs, and elevate product quality to new heights.

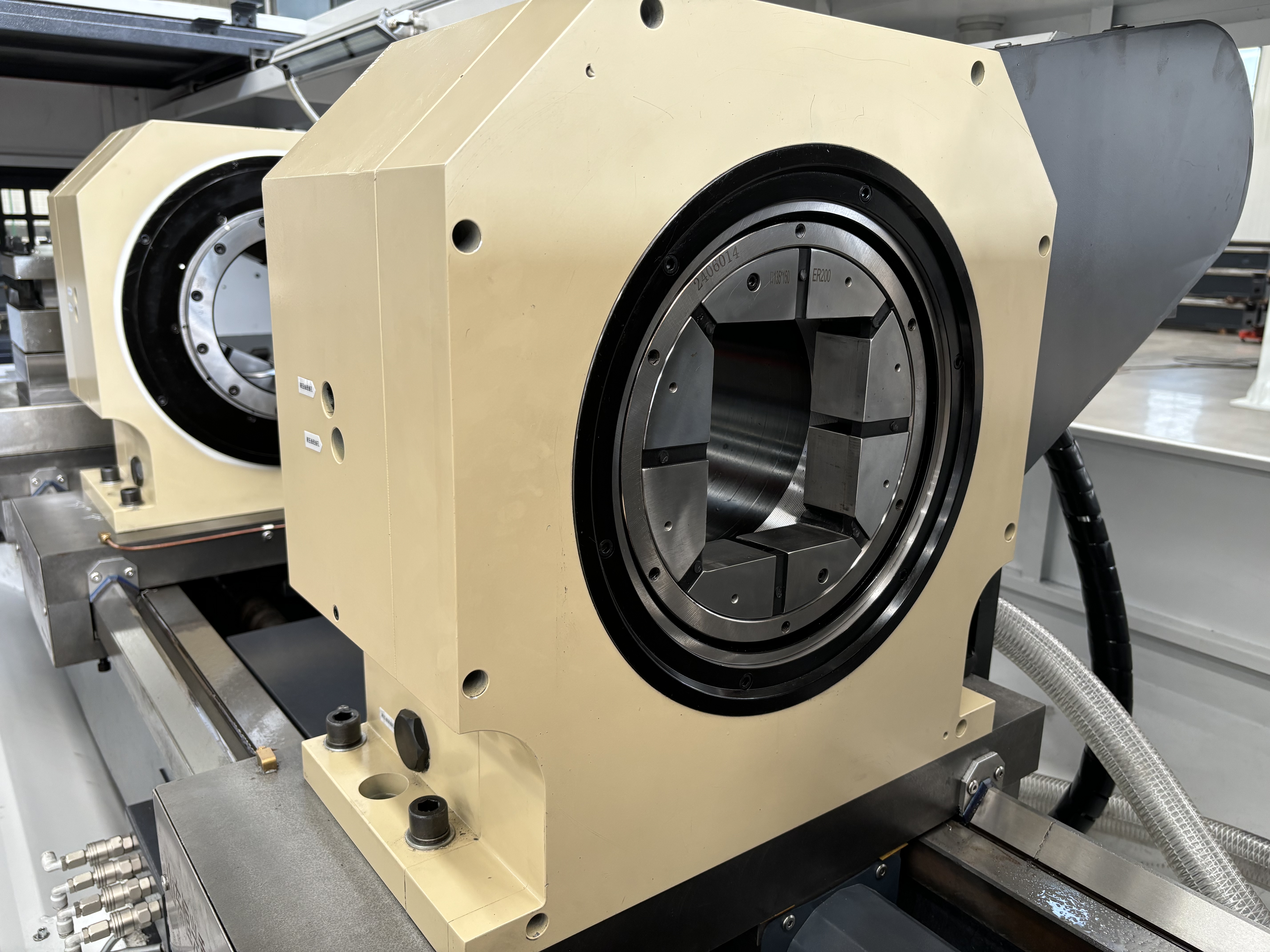

The core competitiveness of dual-spindle CNC lathes stems from their unique dual-spindle design. Compared with traditional single-spindle lathes, the equipment is equipped with two independent spindle systems that can operate synchronously or asynchronously, enabling an efficient mode of "one-time clamping, two-end processing". During processing, the main spindle and sub-spindle complete workpiece transfer through precise docking without secondary positioning. This not only significantly shortens the processing cycle but also fundamentally eliminates positioning errors caused by multiple clampings, controlling dimensional accuracy and geometric tolerances within 0.001mm.

In terms of functional integration, modern dual-spindle CNC lathes have shattered the limitations of the single turning function that defined older machining equipment. Shandong Hengxing Heavy Industry’s offerings, in particular, stand out for their advanced capabilities. Each lathe is equipped with a dual-channel and dual-program control system, a sophisticated setup that allows for the simultaneous handling of processing procedures for parts with different sizes and shapes at both ends. This means that a single machine can tackle complex, multi-step tasks that would previously have required multiple pieces of equipment, significantly reducing production line complexity and floor space requirements. Moreover, recognizing the diverse needs of its customers, Hengxing Heavy Industry has designed its lathes to be highly customizable. Customers can easily expand the machines’ capabilities to include composite processing functions such as milling, drilling, and tapping, transforming the lathe into a all-in-one machining center. The main drive system further enhances performance, utilizing either a frequency conversion drive or a servo main drive scheme. By adopting an arc tooth belt direct drive for the spindle, the lathes achieve stepless speed regulation, ensuring smooth, stable, and near-silent operation— a crucial advantage in environments where noise pollution and vibration can affect both worker comfort and processing precision. The spindle speed range, spanning from 200 to 2200 rpm, is carefully calibrated to accommodate the processing needs of a wide variety of shaft and rod parts, with diameters ranging from φ20mm to φ350mm. To further embrace intelligent manufacturing, these lathes can be seamlessly integrated with automatic feeding machines, truss robots, and chip removal devices. This integration creates a fully automated, unmanned production line that covers every step from blank loading to finished product unloading, boosting production efficiency by an impressive 50% to 80% compared to traditional, manually operated equipment.

The ever-expanding range of industry application scenarios is a testament to the immense market value of dual-spindle CNC lathes. In the automotive manufacturing sector, for instance, these lathes have become indispensable for processing key components such as engine crankshafts and camshafts. Their ability to maintain consistent precision across high-volume production runs ensures that every part meets the strict quality standards of the automotive industry. This is especially critical for new energy vehicles (NEVs), where components like motor shafts and battery casings demand ultra-high precision and uniformity to ensure optimal performance and safety. Dual-spindle CNC lathes, with their stable performance and reliable precision, have emerged as the go-to processing equipment for NEV manufacturers, supporting the rapid growth of this vital industry. Beyond automotive, dual-spindle CNC lathes have also made significant inroads into industries such as engineering machinery, hydraulic transmission, and precision instruments. In engineering machinery, they are used to produce symmetric structural parts like hydraulic cylinder rods, where their two-end processing capability ensures perfect alignment and strength. In the field of precision instruments, their ability to handle small, intricate parts with micron-level precision has made them essential for manufacturing components used in medical devices and optical equipment. Across all these sectors, dual-spindle CNC lathes are playing a pivotal role in driving quality improvement and efficiency enhancement, helping manufacturers stay competitive in a global market.

Looking ahead, the future of dual-spindle CNC lathes is poised for even greater innovation, fueled by advancements in materials science and control technology. As manufacturing demands continue to evolve, these lathes will need to adapt to process newer, more challenging materials such as high-strength alloys and composite materials— materials that are increasingly used in aerospace and automotive applications for their lightweight and durable properties. To meet this demand, future dual-spindle lathes will likely see breakthroughs in higher rigidity, which will enable them to handle the increased cutting forces required for tough materials without compromising precision. Additionally, efforts to reduce vibration and noise will be intensified, further improving processing accuracy and creating a more comfortable working environment. Another key area of development will be expanding material applicability, allowing the lathes to process a broader range of materials with minimal adjustments. These advancements will not only enhance the performance of dual-spindle CNC lathes but also position them as a key driver of the high-quality development of the global manufacturing industry. As companies like Shandong Hengxing Heavy Industry continue to invest in R&D and push the boundaries of what is possible, dual-spindle CNC lathes will remain at the heart of manufacturing’s journey toward greater precision, efficiency, and intelligence.

Hot News

Hot News2025-03-01

2024-08-09

2024-08-02